गेहूं के विभिन्न अंत उत्पादों के पोषण संबंधी मूल्य पर प्रसंस्करण का प्रभाव

To meet the energy need of the ever growing world’s population, wheat is the second most widely gowned cereal after rice in the world. The importance of wheat is mainly due to the fact that its grain can be processed into various end products like flour, semolina, and other bakery products. The quality of these products is directly proportional to preserving the nutrient density of wheat while processing. Table 1, shows the nutritional composition of different end products which is comparable with the whole wheat grains. Processing of wheat grain involves different regulated steps right from the harvesting the grains to the production of flour to be used to form various end products. Therefore, enough care should be taken at each step while processing. In this article we have highlighted the nutritional loss of various end products while processing.

Table 1: Nutritional profile of some wheat products (amount /100g grain)

|

S.No |

Nutrient |

Whole grain |

Wheat bread |

Semolina |

Kellogg

|

Spaghetti Cooked |

Wheat, durum |

Chapatti |

|

|

Carbohydrate |

|

||||||

|

1. |

Total carbohydrate (g) |

72.5 |

47.5 |

72.8 |

77 |

26.5 |

71.1 |

49 |

|

2. |

Dietary fiber (g) |

12.1 |

3.6 |

3.9 |

15 |

4.5 |

- |

4.04 |

|

|

Protein |

|

||||||

|

1. |

Protein (g) |

13.6 |

10.9 |

12.7 |

15 |

5.3 |

13.7 |

8 |

|

|

Fats |

|

||||||

|

1. |

Total fat (g) |

1.8 |

3.6 |

1.1 |

1.6 |

0.5 |

2.5 |

8 |

|

2. |

Saturated fatty acid (g) |

0.3 |

0.8 |

0.2 |

0.3 |

0.1 |

0.5 |

- |

|

3. |

Monounsaturated fatty acid (g) |

0.25 |

0.8 |

0.1 |

0.6 |

0.1 |

0.3 |

- |

|

4. |

Polyunsaturated fatty acid (g) |

0.75 |

1.4 |

0.4 |

0.7 |

0.2 |

1 |

- |

|

5. |

Omega-3-fatty acid (mg) |

38 |

135 |

37 |

- |

10 |

48 |

- |

|

6. |

Omega-6-fatty acid (mg) |

738 |

1300 |

393 |

- |

203 |

930 |

- |

|

|

Vitamins |

|

||||||

|

1. |

Vitamin A (IU) |

9.1 |

- |

- |

- |

3 |

|

- |

|

2. |

Vitamin E (mg) |

0.8 |

0.2 |

- |

- |

0.3 |

|

- |

|

3. |

Thiamine (B1) (mg) |

0.41 |

0.4 |

0.3 |

- |

0.1 |

0.4 |

- |

|

4. |

Riboflavin (B2) (mg) |

0.25 |

0.3 |

0.1 |

- |

- |

0.1 |

- |

|

5. |

Niacin (B3) (mg) |

6.3 |

5.2 |

3.3 |

- |

0.7 |

6.7 |

- |

|

6. |

Pantothenic acid (B5) (mg) |

1.0 |

0.8 |

0.6 |

- |

0.4 |

0.9 |

- |

|

7. |

Pyridoxine (B6) (mg) |

0.3 |

- |

- |

- |

- |

0.4 |

- |

|

8. |

Folate (B7) (µg) |

44 |

85 |

72 |

- |

5 |

43 |

- |

|

|

Minerals |

|

||||||

|

1. |

Calcium (mg) |

34 |

142 |

17 |

40 |

15 |

34 |

- |

|

2. |

Iron (mg) |

3.9 |

3.5 |

1.2 |

- |

1.1 |

3.5 |

- |

|

3. |

Magnesium (mg) |

138 |

48 |

47 |

- |

30 |

144 |

- |

|

4. |

Phosphorus (mg) |

345.8 |

155 |

136 |

421 |

89 |

508 |

- |

|

5. |

Potassium (mg) |

405 |

184 |

186 |

475 |

44 |

431 |

- |

|

6. |

Sodium (mg) |

5 |

521 |

1 |

3 |

3 |

2 |

- |

|

7. |

Zinc (mg) |

2.9 |

1.2 |

1.1 |

- |

0.8 |

4.2 |

- |

|

8. |

Copper (mg) |

0.4 |

0.2 |

0.2 |

- |

0.2 |

0.6 |

- |

|

9. |

Manganese (mg) |

3.8 |

1.1 |

0.6 |

- |

1.4 |

3 |

- |

|

10. |

Selenium (µg) |

70.6 |

28.8 |

- |

- |

25.9 |

89.4 |

- |

|

|

Others |

|

||||||

|

1. |

Water (g) |

10.25 |

35.7 |

12.7 |

4 |

67.1 |

10.9 |

- |

|

2. |

Energy (kJ) |

1420 |

1114 |

1507 |

1348 |

519 |

1419 |

1275 |

|

3. |

Ash (g) |

1.58 |

2.2 |

0.8 |

2.4 |

0.4 |

1.8 |

- |

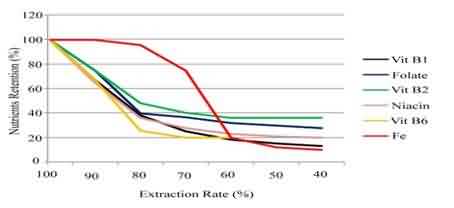

Micronutrient of wheat grain & flour and its stability

Whole grain is blessed with good content of vitamins such as B1 (thiamine), B2 (riboflavin), niacin, B6 (pyridoxine), E, and micronutrients like iron and zinc. On the other hand, most of these nutrients are concentrated in the outer layers of the wheat grain which are lost significantly during milling process. The loss of these micronutrients is inversely proportional to the extraction rates of flour. Extraction rate of flour is defined as the recovery of flour/kg of whole wheat grain. Higher the extraction rate, higher the recovery of flour which leads to lower loss of micronutrients and vice-versa

In foods, the stability of vitamins is more wobbly than that of minerals because vitamins are sensitive to heat, oxidising and reducing agents, light, and other kinds of physical and chemical stress. Most of the vitamin losses occur during baking, which is the most common process all wheat flour products go through. Although baking temperatures are high (over 200°C), the temperature inside the product is significantly lower, and over 70 percent of the vitamins remain unaltered. Similarly, between 65 and 85 percent of vitamins remain intact after cooking pastas. A detailed nutritional loss at different step of processing is given in Fig. 1, Table 2 and 3.

Fig. 1: Loss of nutrients from wheat grain while milling

Table 2: Nutrient losses during bread baking

|

S.No. |

Nutrients |

% Loss |

|

1. |

Vit A |

10-20 |

|

2. |

Vit B1 |

15-25 |

|

3. |

Vit B2 |

5-10 |

|

4. |

Niacin |

0-5 |

|

5. |

Folic acid |

20-30 |

Table 3: Losses of vitamins in long Durum wheat pasta after drying and cooking

|

S.No. |

Nutrients |

% Loss after drying (750C) |

% Loss after cooking |

|

1. |

Vit A |

13 |

17 |

|

2. |

Vit B1 |

0 |

32 |

|

3. |

Vit B6 |

5 |

35 |

|

4. |

Niacin |

0 |

30 |

Effect of cooking of wheat flour on dietary fibre:

With extrusion-cooking of wheat-flour, even at mild conditions, the solubility of the dietary fibre increases which seems to be dependent on the water content used in the process. The lower the content of water, the higher the solubilization of the fibre, at least for whole-grain wheat flour and wheat bran. An increased solubility of the fibre has also been obtained with severe popping of wheat, whereas baking (conventional and sour-dough baking), steam-flaking and drum-drying had only minor effects on dietary fibre components. One reason why popping caused an increased solubility of the fibre was that the outer fibrous layers were removed and the content of insoluble fibre decreased. A loss of insoluble dietary fibre has also been reported with autoclaving of wheat flour, which was attributed to degradation of the arabinoxylans.

Baking reduces the protein efficiency ratio of baked products:

Protein efficiency ratio (PER) is based on the weight gain of a test subject divided by its intake of a particular food protein during the test period. PER=Gain in body mass (g) /Protein intake (g). Several work have reported that baking has large negative effect on the PER of baked products compared to unbaked products. Baking of griddlecakes for 2 min at 2040C reduces PER by 17.8%. Similarly, baking of cookies and muffins for 10 and 23 min at 1770C and 2040C reduces PER by 15.5% and 14.5% respectively. Deterioration in protein quality with baking has been attributed to the formation of crust which leads to poor digestibility and destruction of lysine.

Authors:

Om Prakash Gupta*, Pradeep Sharma and R.K. Gupta

Directorate of Wheat Research, Karnal-132001, Haryana

*Corresponding author-Email: