ऊंची सुरंग: पुष्प फसल उत्पादन के लिए वरदान

Solar radiation, temperature and precipitation are the main drivers of crop growth, therefore agriculture has always been highly dependent on climate patterns and variations.

To overcome all these problems related to climate change, we have to work on Structural and functional design of different Protected structures like Greenhouse, Polyhouse, High tunnels, Low tunnels, shade net house and Low cost environment control greenhouse. Among all these High tunnel is really boon for floral crop production.

High tunnels are passively vented, solar greenhouses that are used to lengthen the production and marketing season of cut flowers. No artificial heating/cooling or ventilation system is used within the high tunnel, and the only external connection is water for drip or micro-irrigation.

Most high tunnels are covered with a single or double layer of polyethylene plastic and have a useful life of near about 20 years if properly constructed and maintained. Crops within high tunnels are usually grown directly in the soil rather than artificial growing media, but soil-less substrate (compost, perlite, and water) can be used for crop production within high tunnels.

High tunnels are very effective in collecting radiant energy from sunlight and using this energy to increase air and soil temperature to accelerate crop growth. Thus, in areas with abundant sunlight, high tunnels will be very effective for early-season harvest and lengthening the growing season.

High tunnels facilitate intensive crop production on a small land area and are conducive to sustainable farming practices such as inter cropping, cover cropping, compost application and biological pest management.

Crops within the high tunnels are protected from environmental stresses such as drought, wind, hail, rain and intense sunlight. Heavy rainfall prevents soil erosion within the high tunnel. The dry environment within the high tunnel keeps the plant canopy dry and reduces diseases and weed growth. High tunnels also physically exclude many pests from attacking the crop including insects and wildlife.

Tunnels Types

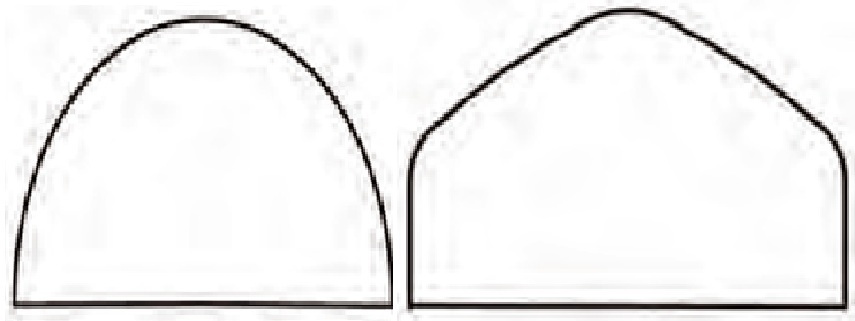

There are two main structural designs for high tunnels: Quonset and Gothic. Quonset structures have a round roof with slightly shorter and curved side walls (Figure A), while Gothic structures have a pointed peak (A-frame) with straight side walls (Figure B).

Gothic structures tend to shed snow and ice better than Quonset structures. Gothic structures also allow for a peak or gable vent to be added to the structure which facilitates air movement and ventilation.

1. Gothic tunnels:

Gothic style tunnels have a peaked roof and straight side walls. The steeper roof sheds snow and ice more readily than the rounded roof of a quonset tunnel. Additionally, condensing moisture within the tunnel tends to run down the sloping roof to the sides, rather than dripping on the plants below.

The straight sides provide more usable growing space along the outer walls than the typical rounded quonset. In addition, the greater height of the gothic tunnel permits the production of taller crops. This height also helps increase air circulation, especially when vents are installed at the gable-ends. Gothic style tunnels are built only as single bay structures.

2. Quonset tunnels:

Quonset tunnels have a rounded roof that generally extends from “ground to ground,” giving the structure a semi-circular shape. Quonsets are among the simplest and least expensive tunnels to construct.

The low tunnel height along the sidewalls, however, limits the types of crops that can be grown in that space. Alternately, the hooped roof may be set on straight sidewalls to increase the vertical growing space along the outer walls.

The rounded roof of the quonset tunnel does not shed snow readily, making them more likely to suffer damage from a heavy snow load. Spacing the hoops at closer intervals and/or bracing the bows with cross braces are ways to strengthen the structure.

Another alternative is to remove the plastic covering during the winter. Tunnels constructed from PVC pipe are particularly vulnerable to collapse from snow. Quonset style tunnels may be either single bay or multi-bay. The Haygrove tunnel is an example of a multi-bay, three-season tunnel that can be used to cover larger acreages.

There is difference in structural design of Quonset and Gothic type high tunnel. The Quonset style looks like an arch while the Gothic style comes to a peak in the center.

The peaked roof of the Gothic style allows the trusses that provide additional support to be well above head height, and it is able to shed snow better than the Quonset style. Another advantage of the Gothic style of structure is that the walls go straight up, allowing equipment such as rototillers or cultivators to work closer to the wall. The traditional Quonset style usually begins its curving arch right at soil level.

Figure A : Quonset style High Tunnel Figure B: Gothic style High tunnel

End walls

End walls can vary considerably in their design. They may be framed with wood or metal, or they may simply have an unframed plastic curtain that can be rolled up or pulled back. Framed end walls, which add strength and stability to the high tunnel, are constructed after the tunnel itself is assembled.

Fixed end walls may have just a single or double storm door/screen door built into one or both ends for worker access. Some framed end walls have a large rectangular section hinged at the top so that the end wall can be opened.

These may completely swing open or fold up accordion style. Others have sliding doors or removable panels. Tunnels in which a large portion of the end wall can be opened or removed not only have better ventilation, but also afford easier access for equipment.

Gable end vents installed near the peak of gothic style tunnels offer additional air exchange. The choice of end wall design will depend largely on tunnel size, grower needs, construction costs, and personal preference.

Tunnel size

There are a number of factors that should be considered when deciding on the size of the high tunnel. Obviously, the tunnel should be tall enough for workers to walk into comfortably.

The amount of maximum vertical space required for the various crops that will be grown in the tunnel is another determining factor for tunnel height.

Adequate square footage should be available for planting, producing, and harvesting the various crops, as well as for maneuvering small tractors or any other equipment that will be used in the tunnel. Typical tunnels are 9 to 15 feet tall, 15 to 30 feet wide, and 60 to 96 feet long.

Size will also affect the environment within the tunnel, especially heat retention and air movement. For example, while narrow tunnels are easier to ventilate than wider ones, narrow tunnels also experience more heat loss on cold nights. Long tunnels are more difficult to ventilate, especially if they are wide. Tall, wide houses typically retain heat in winter better than short, narrow tunnels.

Movable vs. Permanent

The high tunnel concept seems to suggest mobility; however, tunnels are often built in such a way that they are difficult to move without considerable effort. As a result, they often remain on the same site for a number of years before being moved to another location (semi-permanent) while others are never moved (permanent).

Typically, permanent/semi-permanent structures have in-ground posts, galvanized steel bows, and rot resistant wood baseboards. Endwalls can be constructed of steel or wood. When tunnels are not moved each year, the grower will need to implement a good crop rotation program.

Tunnels that remain in the same location year after year, where either no rotation or a short rotation is practiced, can have high levels of soil pathogens and insect pests, leading to serious crop losses.

Fertilizer salt build-up will become a problem unless the plastic covering is removed to allow precipitation to flush salts from the soil. Once in place, soil preparation in these tunnels each year can present a challenge.

Hinged endwalls permit easier access for small equipment. When the endwalls are fixed, soil preparation will need to be accomplished by hand or with a small power tiller.

Movable tunnels may be built with PVC bows, which not only makes them lighter, but cheaper to construct. Only quonset style tunnels can be built from PVC. Tunnels built with steel bows but without in-ground posts are easier to move; however, tunnels that sit on top of the ground will be more vulnerable to wind damage unless they are well-anchored.

Another way to make the tunnel more mobile is to build it on skids or runners. An important advantage to movable high tunnels is the ability to relocate them to a new site each growing season to facilitate crop rotation. The soil in movable tunnels is worked prior to erecting the structure.

Selecting material

Covering material :

One or two layers of greenhouse-grade polyethylene (4 to 6 mil) are used as the covering. Those covered with two sheets have an air layer in between, thus offering better insulation, and consequently, more cold protection.

Two layers will require an inflation fan, which in turn requires access to electricity or installation of a solar system for power. Occasionally growers will insert Styrofoam blocks between the layers of plastic if they do not have electricity to their tunnels. While the second layer of plastic does offer greater heat retention, it also reduces light penetration into the tunnel.

When using a single layer of plastic, low tunnels or floating row covers can be used within the high tunnel for additional cold protection.

The plastic film used to cover a high tunnel can be treated to reduce condensation dripping on plants. Additionally, an infrared re-radiate material added to the film reduces overnight heat loss. As the plastic ages, the amount of light transmitted through it will be reduced.

The plastic covering should be replaced approximately every 4 to 5 years. When a high tunnel is used for the summer production of cool-season crops, the frame is covered with shade cloth.

The shade cloth, which is used either alone or on top of the polyethylene, reduces light intensity and air temperature within the tunnel. The combination of shade and irrigation keeps soils cooler, as well.

Frame material:

Historically, wood was commonly used to frame greenhouses, but it is has gone out of fashion because of its relatively high maintenance cost and the availability of steel greenhouses.

Steel is the best material for a high tunnel frame. The best greenhouse structures are made of high tensile strength steel covered with a very good galvanized coating to prevent rust.

An alternative to steel for the structural members of a high tunnel is polyvinyl chloride (PVC) pipe. Price is PVC’s only real advantage compared to steel. Mainly it is used in farmer-built tunnels.

Tunnels whose bows are made of PVC pipe are more prone to collapse under snow load and wind. Only narrow high tunnels with a Quonset-shape and smaller walk-in or caterpillar tunnels can be constructed of this weaker material. It should be noted that PVC is a persistent poison that harms human and animal health and pollutes the environment during manufacture and disposal

Site selection and orientation

Tunnel location and orientation, in addition to the site soil conditions, are essential to production success. Site selection is more critical when the high tunnel is built to be a permanent structure; however, it is an important consideration even when constructing semi-permanent or movable tunnels. Select a naturally fertile, well-drained site in full sun that is near a reliable water supply for irrigation.

A relatively level surface is generally needed for the high tunnel frame. An exception is the multi-bay Haygrove tunnel, which does not require a level site. Avoid hilltops or other areas subject to high wind. Providing a windbreak can help reduce the threat of wind damage to the tunnel. On the other hand, the site should have good air flow for ventilation.

Stay away from low sites that are poorly drained or likely to serve as frost pockets, as well as sites too close to wooded areas. Orienting the house perpendicular to the prevailing wind on the farm will help facilitate cross ventilation in the tunnel. For maximum sun exposure during the fall and winter, the tunnel should be oriented in an east-west direction. When constructing multiple tunnels, make sure that they do not shade one another.

Placing the tunnel on ground that is slightly higher than the surrounding area helps prevent water from flowing into the tunnel during heavy rains. Alternately, a shallow trench along the outside perimeter can keep water from entering the tunnel.

Procedure of High tunnel construction:

After the site and general design of the high tunnel has been chosen, the structure can be constructed. Both spring and fall are excellent times of the year to build a high tunnel. The soil is amenable to construction, and the air temperature is suitable for pulling and stretching plastic over the structure. If building on a site which is presently in sod, the sod can be tilled after most of the high tunnel has been constructed.

The next step is to place the corner ground posts of the high tunnel so that the structure is ultimately square. The Pythagorean Theorem can be used to establish a 900angle at each corner.

The Pythagorean Theorem states the square of the hypotenuse of a 90° triangle is equal to the sum of the squares of the other two sides. Once one corner is square, the other three corner posts can be set so that the diagonals (length from one corner post to the opposite end corner post) are equal. For example, a 30 ft x 96 ft high tunnel will have a 100.5 ft length diagonal (302 + 962) if the structure is square.

After the corner posts have been squared, they can be backfilled with cement to provide support for the structure. Obviously cement makes the structure permanent, so if there are plans to move the structure in the future, this step may be avoided.

The remaining high tunnel ground posts are driven into the soil as straight as possible to various depths (usually no less than 18 inches) with a sledge hammer or post driver. A post level will be very useful in making sure each post is plumb.

Also a leveling line (mason twine) connected to the bolt holes of each corner post can be used to drive each post to a depth which is level. A positioning or spacing jig can be used to evenly space the ground posts.

The bows of the structure typically are 2-3 pieces and can be loosely assembled on the ground. Each bow is then inserted into the ground post and secured with 1-2 carriage bolts. Placing each bow in the ground post will require approximately 3 workers.

After the bows are secured in place, the purlins should be attached to the bows. Purlins are smaller diameter pipes which are bolted (or clamped) to the bows to provide stability to the structure. Each high tunnel frame should have 1-3 purlins. Cross-braces can be attached to provide increased strength to the high tunnel frame.

After the purlins have been added to the structure, the baseboards and hip boards can be placed on the high tunnel. Baseboards and hip boards add strength to the base of the frame. For most high tunnel frames, 2 inches x 6 inches x 10 feet wood (or recycled plastic) boards are suitable. Pressure treated wood can be used for both hipboards and baseboards.

Each section of baseboard is bolted onto the ground post or secured with a pipe strap. The baseboard and hipboard must be level across the length of the high tunnel. Each joint between sections can be spliced with a small segment of board.

Hipboards are attached 5-8 feet above the baseboards. Hipboards provide additional strength to the structure and are the boards in which the plastic covering the high tunnel structure is attached. Aluminum channel lock can be secured to the hipboard to provide a location for securing the plastic.

After the frame has been assembled, the end walls can be constructed. End walls vary in design from a simple fabric curtain to a wood-framed structure with doors. End walls provide strength to the high tunnel and should be built to provide easy access of people and machinery.

End walls can be covered with polyethylene plastic, polycarbonate or plywood. The north-facing end wall can be covered with double layer of polyethylene plastic to provide greater protection from the north wind. Some growers will completely remove the end wall coverings during warm weather.

The plastic covering can be placed over the high tunnel structure after construction of the frame and end walls has been completed. There are many types of greenhouse plastics, but the plastic should be a UV- (ultraviolet light) treated plastic, 6 mil in thickness, with a useful life of approximately 4 years.

IR (infrared) blocking plastic is also available and will provide better heat retention. A calm day with moderate temperatures will be optimal for covering the structure. Plastic should not be pulled over the structure if temperatures are lower than 60oF since it will be difficult to obtain a good stretch on the plastic. Ideally, the plastic should be not flap against the bows.

At least 4-5 people will be needed to pull the plastic over the high tunnel. The plastic comes in a roll which is unrolled along the length of the house. After unrolling the plastic, a handful of the plastic can be folded around a tennis ball at various distances.

Rope is then tied to this ball and thrown over the frame. Carefully, the plastic is pulled over the structure, making sure it is square with the frame.

The plastic is attached to the frame with wiggle wire or polylock placed in each aluminum channel lock on the hip board. One side should be completely secured first then any slack in the plastic can be pulled and the other side wired. The plastic should be as taut as possible. The channel locks on the end bows are used to hold the plastic to the end walls of the high tunnel.

The plastic is clamped on to a metal roll bar (purlin pipe) which serves as the bar for rolling the plastic up or down on each side wall. A “T- or L”- shaped handle can be made to serve as a hand crank which makes rolling the pipe up easier. Rope can be placed on the sidewalls to hold the plastic sidewall closer to the frame and prevent flapping in wind.

To prevent excessive water movement into the high tunnel, a drainage ditch should be dug to channel water away from the high tunnel. A woven landscape fabric can also be used to divert excess runoff water and prevent weeds from growing close to the high tunnel.

Rain gutters can also be secured to the hipboard and used to channel water into a storage tank that can be used to irrigate crops within the high tunnel.

Authors:

Rahul Subhash Yadav

Scientist (Agril. Structures & Environmental Management),

ICAR-Directorate of Floricultural Research,

College of Agriculture campus, Shivajinagar, Pune